A circular economy for electrical lorry batteries seems still some method off, however metal recycling professional EMR declares to be making inroads, and to be assisting form the future of the sector.

The present of electrical cars (EVs)– and the advanced high-power batteries on which they run– represents a minute of extensive modification for both metal recyclers and their partners in the UK vehicle market.

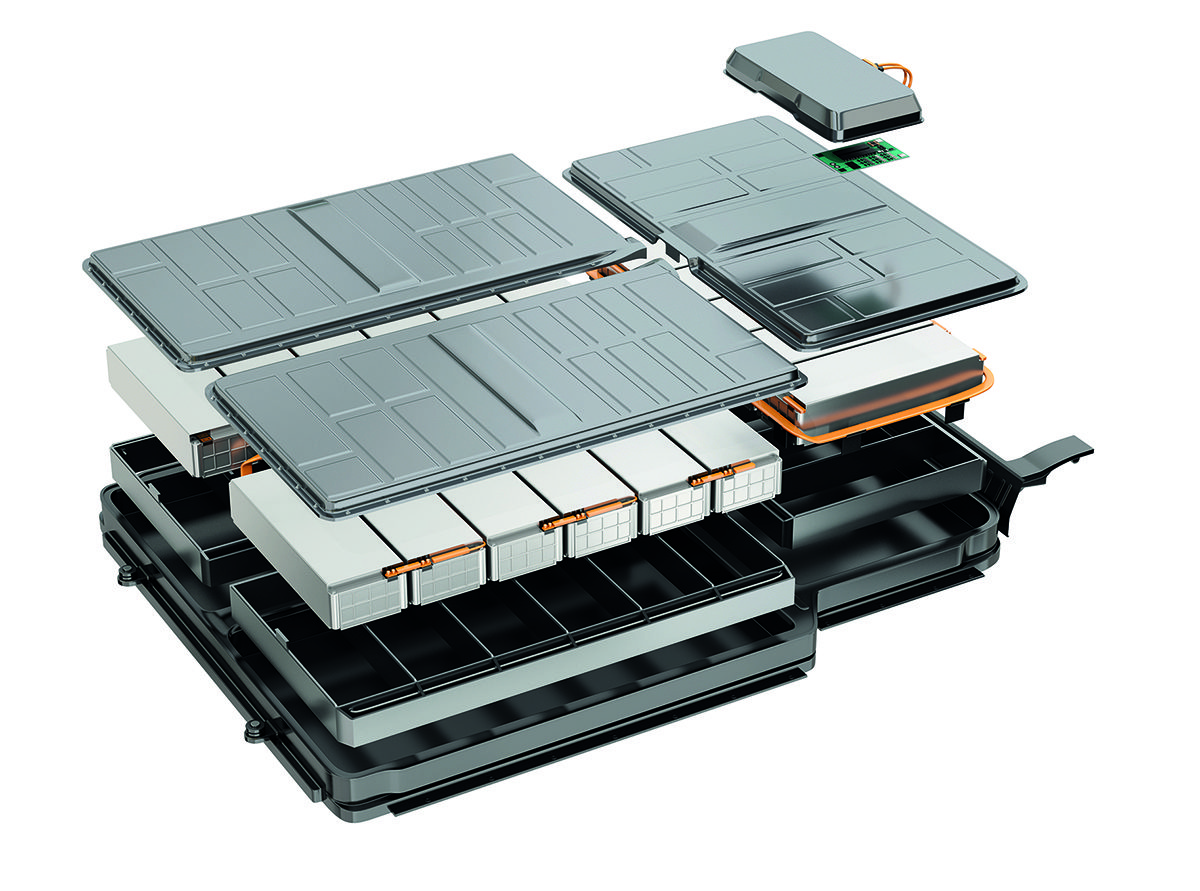

At stake is the possibility of a genuinely circular economy for EV batteries, improving the sustainability of the innovation, while securing the important resources– consisting of lithium, cobalt, and nickel– on which it relies.

” It took 4 years to ideal the procedures for recycling an internal combustion engine (ICE) lorry, however this time we will just have a couple of years to get it right,” states Helen Waters, Head of Electric Battery Recycling at EMR. “A few of the procedures are the very same, however lots of aren’t– from effectively evaluating the health of a battery to disassembly and logistics, there’s a variety of obstacles that EMR has actually determined in developing this brand-new circular economy and we’re currently hectic talking to cars and truck makers, renting business and dealers to get it right.”

EMR recycles countless end-of-life cars (ELVs) each week at its more than 60 UK websites. As EVs end up being more typical on our roadways, the company intends to keep a market-leading position as a sustainable, accountable, and effective recycler of ELVs.

Yet, the existing generation of high-performance EVs are so dependable, they state, that a lot of will not reach completion of their working lives for a minimum of a years or more. That’s why EMR states it is now dealing with the vehicle market, utilizing item remembers, guarantee failures and even the batteries utilized in e-bikes and e-scooters to supply the volume of product required to assist scale up a circular economy for EV batteries.

” Our message to the market is to deal with us today so that our companies can team up, whether that is on developing brand-new easy-to-recycle batteries, putting in location the logistics needed for this shift or to even more establish the innovation needed to recycle EV batteries,” states Helen.

A great deal of this work is currently underway. Over the previous 2 years, EMR has actually led a job focused on separating and processing end-of-life EV batteries for re-use or remanufacturing (for renewable resource storage) and, if this isn’t possible, recycling. The RECOVAS consortium unites cars and truck makers, consisting of Bentley, Jaguar Land Rover, and BMW, along with Connected Energy, Autocraft Solutions, the UK Battery Development Centre (UKBIC) and academics from the University of Warwick– an example of the sector-wide cooperation that that will be needed moving forward. The partnership is part-funded by the UK’s Advanced Propulsion Centre.

Waters states she has actually likewise “remained in discussion with OEMs about methods to enhance cars and trucks from the style stage onwards, to enhance the procedure of recycling or re-using their batteries at end of life.

” Automotive producers have their own 2030 sustainability targets in location, and lots of have actually currently vowed to provide a circular economy for their products too. In addition, EU Recycled Material targets– contributed to issues about resource security– indicates the market is currently mindful that service as typical is no longer a choice.”